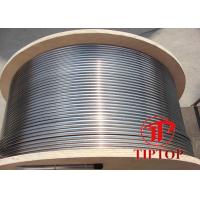

With the leading direction of producing High pressure extra long

stainless steel control line tube(stainless steel coiled tubes),

TIPTOP has become a high-tech industrial company integrating

domestic research and development, production and sales. The

company successfully developed a series of stainless steel testing

cables in 2000. In recent years, the company has been committed to

the research and development of duplex steel and nickel alloy

control lines, and has been widely approved in the international

market.

The company covers an area of 20,000 square meters and a building

area of 12,000 square meters. The company has several stainless

steel tube production lines, tube making units, tube drawing units,

well-type electric furnaces, online vacuum light furnaces and other

production equipment. The company also has a quality inspection

center that meets the national stainless steel tube quality

inspection requirements. The quality inspection center has a 300Mpa

hydraulic test machine, tensile test bench, Vickers hardness

tester, 500°C temperature resistance test furnace, eddy current

flaw detector and a series of stainless steel products. Testing and

inspection equipment to ensure the reliability and stability of the

chemical and physical properties of stainless steel products.

The company annually produces more than 3,000 tons of stainless

steel control lines and other products, sales marked covers both

domestic and overseas, for domestic, we are network-enterprise

company of CNOOC, Petro China and Sinopec, as for international,it

has been widely used in Middle East, Southeast Asia, South America,

Australia and so on.

On the premise of improving the quality of its own brand products,

the company has continuously increased the research and development

of new products, and has cooperated and actively invested with many

domestic universities and scientific research institutions. In

recent years, the company has passed the certifications of CCS, GL,

DNV and other classification societies.

With our support,you will have:

- Technical data, technical guidance and training for free

- Professional engineer to the site for tracking service

- "just-in-time supply"(that is, supply at any time according to the

actual demand of customer), in this way customers achieve zero

inventory, maximize profits.

- Most favorable offer,we take "taking small profits" as the

principle.

- 100% qualified product,Our company will strictly follow the

requirements of relevant technical standards , grasp various links

of production, and ensure product performance .

- sufficient after sales services.

We are looking forward to developing business with friends from

home and abroad on the basis of equality and mutual

benefits!welcoming your enquiries!